PROGRAMMING

Programming in accordance with IEC 61131-3, PLC Next Engineer Choose between network-oriented & free graphical Programming and mix different languages within program organization units(POU)

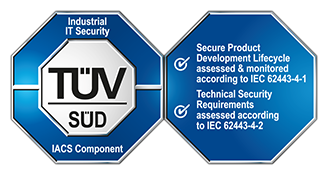

SECURITY

First PLC’s on the market to be certified by TUV SUD for CYBER SECURITY also SIL3 safety controllers. Trusted platform module (TPM) based security. A container based solution in IT Has an integrated python3 interpreter that can be used for machine learning Integrated with linux operating system. Node-RED is installed as a function extension on LINUX OS.

EDGE COMPUTING - Connect the IT and OT worlds.

CLOUD

PLC next control can connect to any cloud like Proficloud.io, amazon’s AWS, Microsoft azure, or your own cloud solution.

SUPPORTED COMMUNICATION PROTOCOLS

PLCnext control has an embedded OPC UA

PLCnext Technology connects the IT and OT worldsMake your application fit for IIoT and Industry 4.0

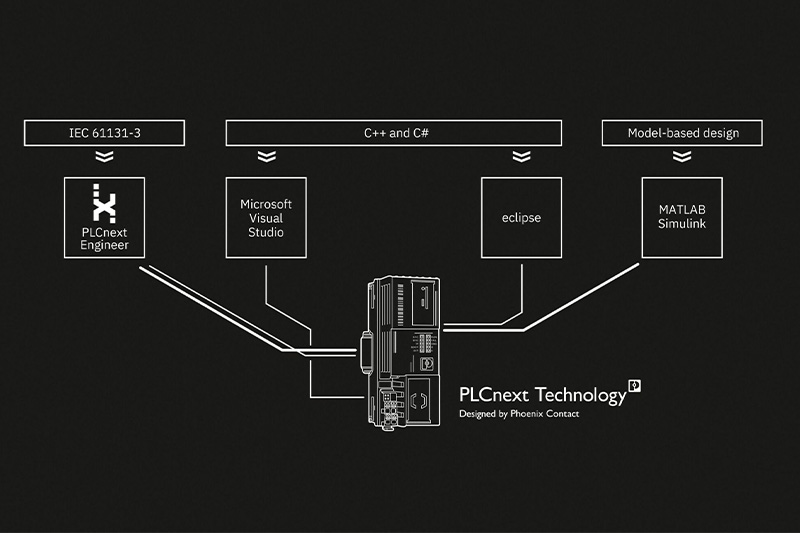

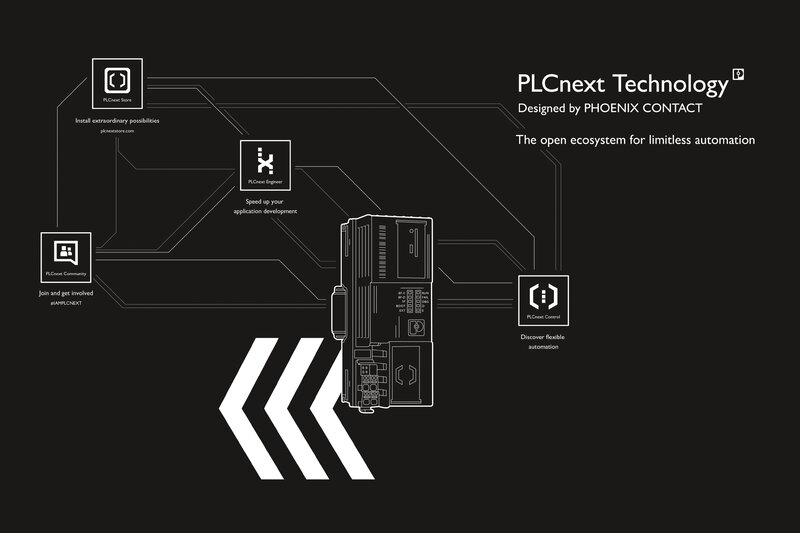

PLCnext Technology is the ecosystem for industrial automation consisting of open hardware, modular engineering software, a global community, and a digital software marketplace. Digitalization and globalization are placing new demands on industrial automation. The precisely-tailored design of the open automation system is just as important as flexible, modular expansion. In addition to standard programming of PLC systems in accordance with IEC 61131-3, parallel programming and the combination of programming languages such as C/C++, C#, and MATLAB® Simulink® in real-time is also possible with PLCnext Control. Accelerate your application development process with the free basic version of PLCnext Engineer. Or use your familiar programming environment – you decide! Through simple cloud integration, the option to use open source software, and the constantly growing expertise of the PLCnext Community, you thus benefit from new forms of collaboration. The resulting solutions apps, software modules, runtime systems, and function extensions are available in the PLCnext Store and ensure enormous time and cost savings when creating applications. This makes PLCnext Technology the ideal ecosystem for your modern automation challenge.

Real-time capability and combinability of IEC 61131-3 and high-level languages

PLCs based on a Linux kernel are characterized by their real-time capability, both for IEC 61131-3 and for high-level languages such as C/C++ and Matlab® Simulink®. The patented task handling allows any combination of IEC 61131-3 code, high-level languages, and model-based tools in one task. Connect directly to Proficloud or any other cloud and integrate individual cloud services. Use the data from your system to optimize your processes. As a result, you increase the quality of your products, reduce costs, and do not have to intervene in running plants. Your data is perfectly protected because PLCnext Control is secure by design in accordance with IEC 62443. PLCnext Control features scalable controllers with an IP20 degree of protection. From modular controllers for basic applications to centrally managed high-performance controllers up to PC-based edge devices, this product family always offers a suitable solution for your project. The modular controllers give you flexibility for your station structure. Choose from a wide range of I/Os or extend the interfaces and functionality of the controller with modules to be connected on the left. If you want to implement AI or edge applications, our portfolio also offers specially optimized hardware for this. New technologies such as OPC UA, TSN, and 5G can also be integrated, thanks to the open Linux core. PLCnext Control thus offers a high degree of future-proofing.